General Industry & Appliances

In the diverse sector of General Industry and Home Appliances, reliability is non-negotiable. We provide robust solutions designed to withstand the rigors of daily use while maintaining superior aesthetic appeal. By leveraging high-performance materials from global giants like Henkel, we ensure that every product meets rigorous quality benchmarks. Whether it is protective coatings for machinery or sleek finishes for household appliances, our commitment to excellence guarantees superior corrosion resistance, longevity, and a finish that adds lasting value to your products.

Innovation drives the General Industry and Appliances market, and we are at the forefront of this evolution. Our mission is to deliver industrial solutions that combine functional efficiency with premium quality. To achieve this, we collaborate with world-renowned leaders such as Henkel, utilizing their advanced formulations to enhance product performance. From manufacturing heavy equipment to refining the surface technologies of modern appliances, our partnership-driven approach ensures that our clients receive sustainable, high-performance results that stand the test of time.

MTI

1- Home Appliance Solutions

KEY PRODUCTS

BONDERITE C-NE 5088

Neutral cleaner effective at low temperatures (50-80°C) with excellent oil-demulsifying properties1

BONDERITE M-NT 2040

Chromium-free etch passivation for aluminum components (like heat exchangers), approved by Qualicoat and GSB

Nano-Ceramic Coatings

Eco-friendly conversion coatings that significantly reduce sludge generation compared to zinc phosphate, lowering maintenance and disposal costs.

MTI

2 Metal & Steel Processing

We offer specialized chemical solutions for Steel Mills, Rolling Mills, and Coil Coating Lines. These solutions ensure the quality of the metal surface from production to end-user.

Technologies

Coil Pretreatment Solutions: Continuous chemical treatment (cleaning and conversion coating) for steel and aluminum coils to ensure Primer and Topcoat adhesion.

Temporary Corrosion Protection: Oils and fluids applied to raw coils (hot or cold-rolled) to protect against “White Rust” and atmospheric corrosion during storage and transport.

MTI

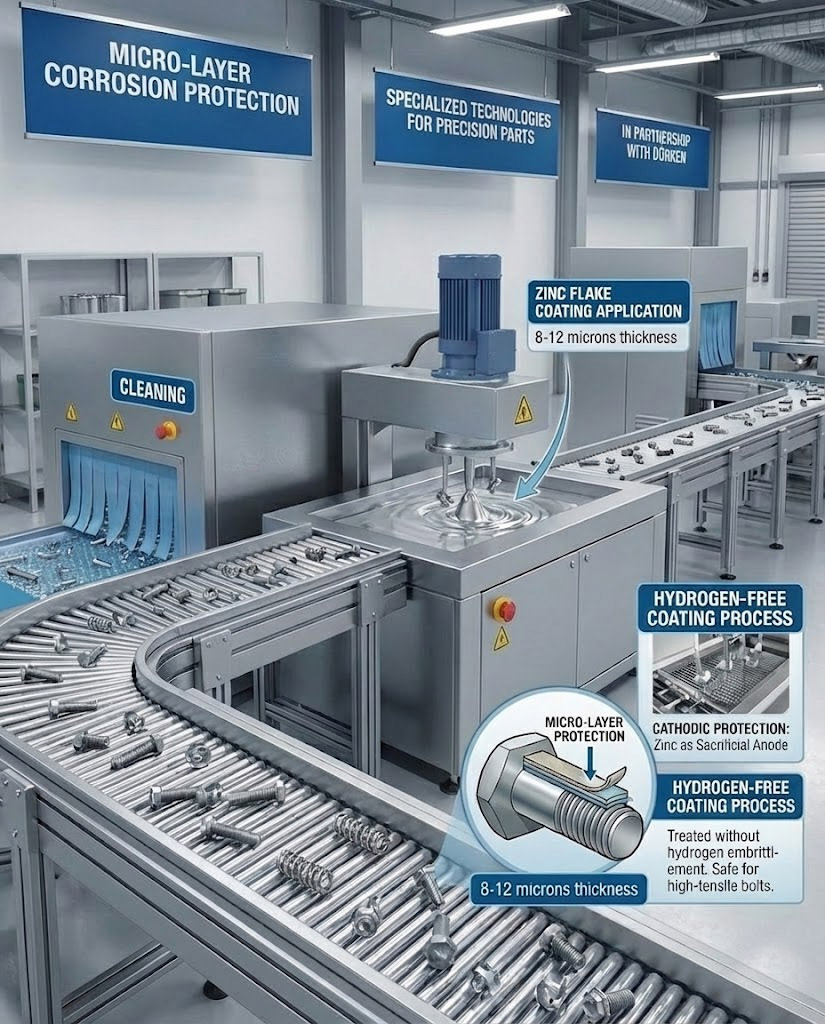

3- Micro-Layer Corrosion Protection

In partnership with Dörken, we provide Zinc Flake Coating technology designed for small, precision-engineered parts (Fasteners, bolts, clips, springs). The challenge is providing high corrosion protection without increasing part thickness, which could interfere with assembly.

Technologies

- Zinc Flake Coating Technology: Superior protection with a micro-layer thickness of only 8-12 microns, maintaining thread tolerance.

- Cathodic Protection: Zinc flakes act as a sacrificial anode to protect the base steel.

- Hydrogen-Free: Eliminates the risk of “Hydrogen Embrittlement,” making it safe for high-tensile bolts.

MTI

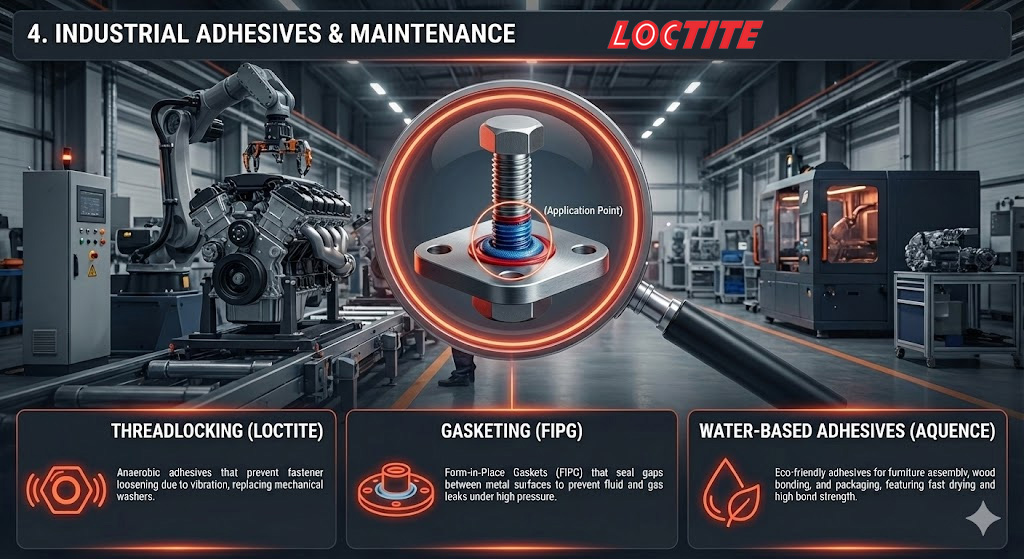

4- Industrial Adhesives & Maintenance

Under Henkel’s LOCTITE brands, we offer comprehensive assembly and maintenance solutions. These cover factory needs to reduce downtime and increase equipment reliability, as well as adhesives for general manufacturing.

Key Applications

- Threadlocking (LOCTITE): Anaerobic adhesives that prevent fastener loosening due to vibration, replacing mechanical washers.

- Gasketing: Form-in-Place Gaskets (FIPG) that seal gaps between metal surfaces to prevent fluid and gas leaks under high pressure.