Surface Treatment (Pretreatment)

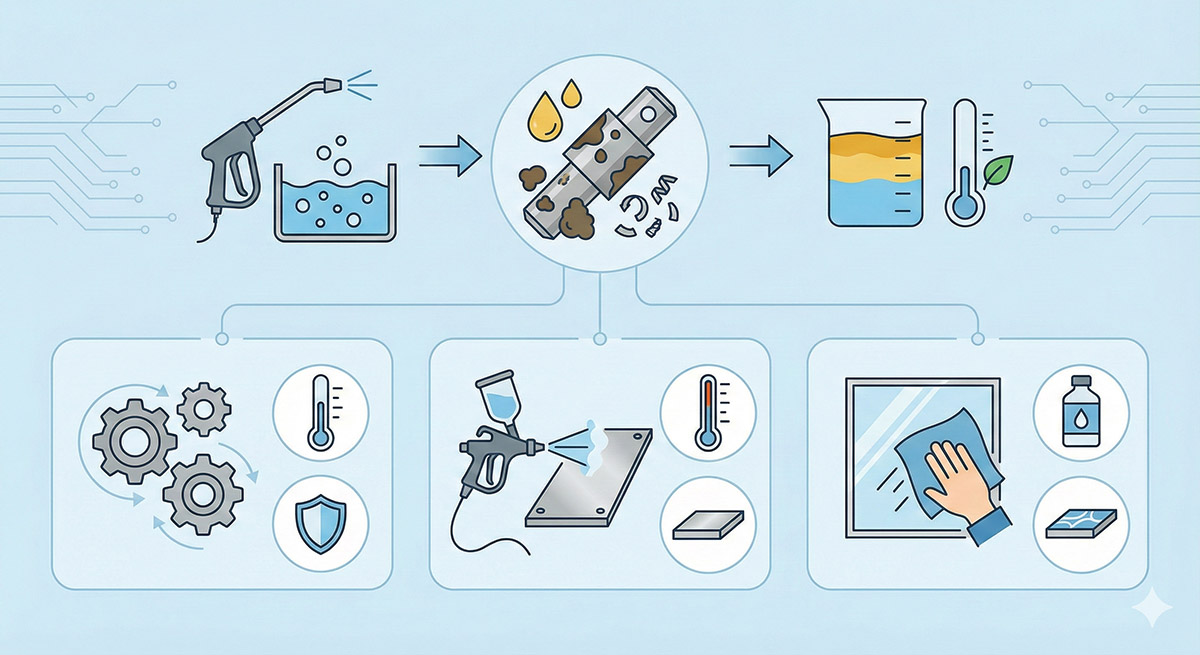

The pretreatment stage is the foundation upon which the entire coating system is built. In this critical phase, we utilize advanced chemical technologies from Henkel to ensure the complete removal of contaminants and the micro-structural conditioning of the metal. This guarantees maximum adhesion for subsequent layers and long-term corrosion resistance for steel, galvanized steel, and aluminum substrates.

We employ advanced water-based cleaners designed to operate efficiently in both spray and immersion lines. These cleaners are capable of removing heavy stamping oils, grease, and metal fines resulting from manufacturing processes. Our portfolio includes neutral and alkaline cleaners featuring “demulsifying” technology to extend bath life, with formulations that operate at low temperatures to conserve energy.

MTI

I- Industrial Cleaners

KEY PRODUCTS

BONDERITE C-AK 7163 CF5

Type: Heavy-duty alkaline cleaner.

Application: Immersion and spray lines for steel, zinc, and aluminum. Removes heavy drawing oils and shop soils.

BONDERITE C-AK RT-1022R

Type: Phosphate-free mild alkaline cleaner.

Application: Multi-metal cleaning (Steel/Aluminum) with minimal surface etching.

BONDERITE C-NE 5088

Type: Neutral Cleaner.

Application: Multi-metal (Steel, Cast Iron, Non-ferrous metals).

Feature: Solvent-free, operates efficiently at 50-80°C, and provides temporary corrosion protection during processing.

BONDERITE C-NE 400

Type: High-efficiency Neutral Cleaner.

Application: Ideal for high-pressure spray processes to clean parts after cutting and stamping.

Feature: Operates across a wide temperature range (10-80°C) and provides surface

BONDERITE C-IC 61110

Type: Acid Cleaner & Etchant.

Application: Deoxidizing and etching aluminum surfaces to remove oxides and welding smut.

TEROSON PU 8550

Type: Solvent-borne cleaner.

Application: Specialized for cleaning glass, ceramic coatings, and painted surfaces prior to direct glazing/bonding.

MTI

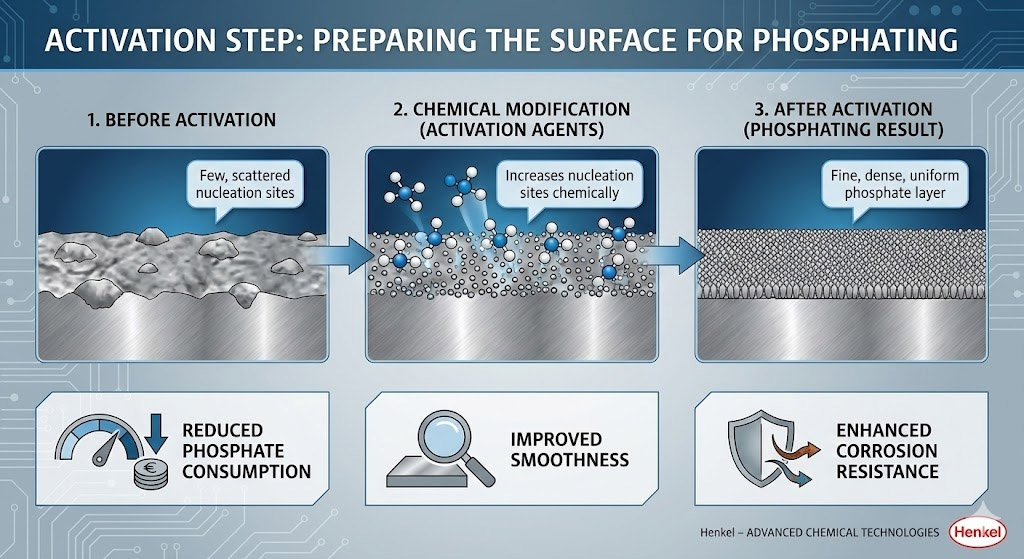

II. Surface Conditioners

The activation step is essential prior to phosphating. These agents chemically modify the metal surface to increase the number of nucleation sites. The result is the formation of a very fine, dense, and uniform phosphate crystal layer, which significantly reduces phosphate consumption and improves the smoothness and corrosion resistance of the final coating.

BONDERITE C-AD RT-1020S

Type: Cleaning Booster / Surfactant.

Function: Added to alkaline baths to boost oil emulsification and wetting properties.

Prepalene X

Function: Zinc Phosphate-based surface conditioner.

Application: Used before Zinc Phosphating for ferrous metals, aluminum, and zinc surfaces.

Feature: Promotes the formation of uniform, fine crystalline coatings and is suitable for use in hard water.

BONDERITE M-AD 130

Type: Accelerator.

Function: Nitrite-based accelerator to speed up the phosphating reaction and reduce treatment time.

BONDERITE C-MC 181

Type: Maintenance Cleaner.

Function: Acidic descaler for cleaning process tanks and heating coils from sludge and scale buildup.

KEY PRODUCTS

MTI

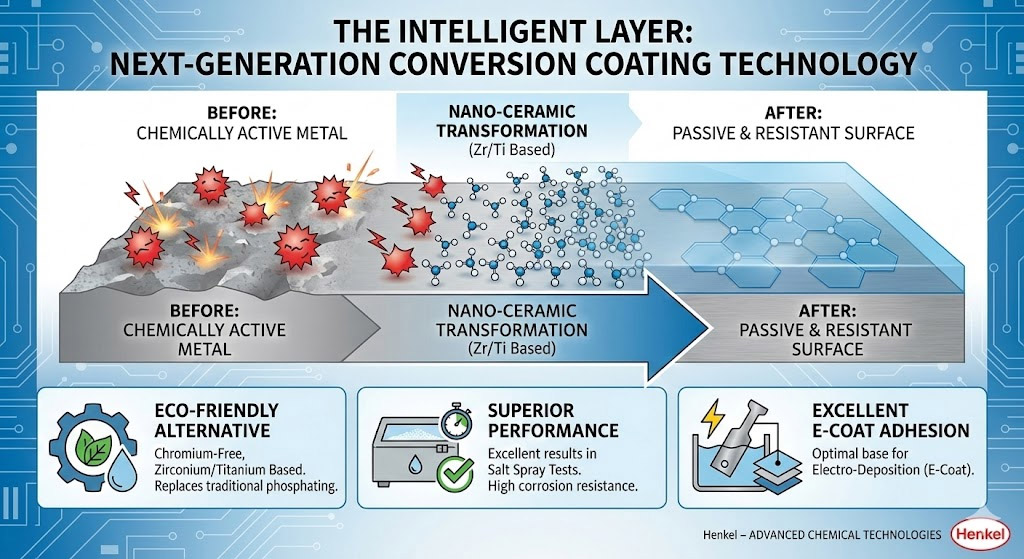

III. Conversion Coatings

This is the “intelligent” layer that transforms the metal surface from chemically active to passive and resistant. We offer the next generation of Chromium-free conversion coating technology based on Zirconium or Titanium (Nano-Ceramic). This technology provides an eco-friendly alternative to traditional phosphating, delivering superior performance in Salt Spray Tests and excellent adhesion for the Electro-Deposition (E-Coat) layer.

KEY PRODUCTS

BONDERITE M-ZN L-3065

Type: Tricationic Zinc Phosphate.

Application: Forms a robust crystalline layer on steel/galvanized steel for maximum paint adhesion.