// Services

Services & Support

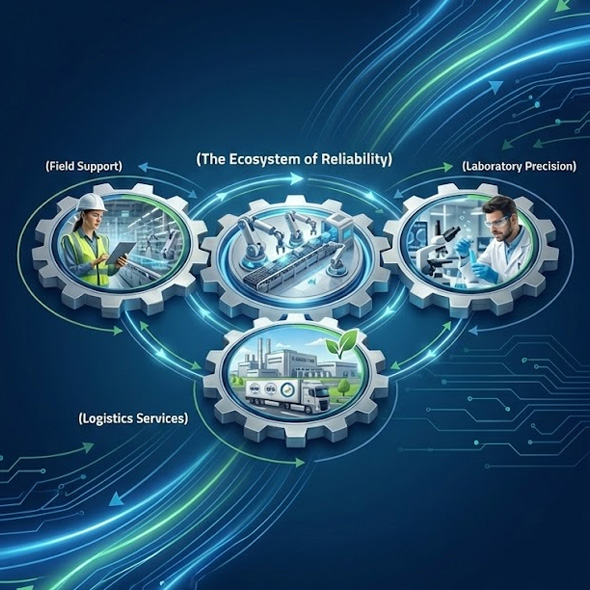

Our commitment to your success extends far beyond the point of sale. We believe that high-performance products require world-class support to deliver their full potential. Through our comprehensive Services & Support division, we integrate directly into your operations, offering on-site engineering, advanced laboratory analysis, and a robust supply chain. We are not just suppliers; we are operational partners dedicated to optimizing your processes, ensuring consistent quality, and securing the uninterrupted flow of your production.

On-Site Technical Support

Our role begins where product delivery ends. We provide “Resident Engineers” or mobile technical teams working alongside your production staff. Our mission is real-time Line Monitoring of all operational parameters (Temperature, Pressure, Time, Concentration).

Key Services

- Troubleshooting: Immediate response to technical issues to prevent line stoppages or defects, including Root Cause Analysis.

- Process Optimization: Periodic review of line performance to reduce chemical, water, and energy consumption, lowering the “Cost per Unit.”

- Training: Technical training for your operators on best practices and safety.

Laboratory & Analytical Services

Quality is measured, not left to chance. MTI owns a fully equipped central laboratory for chemical and physical analysis. We conduct periodic sampling of treatment baths to detect any concentration deviations before they impact the final product.

Analytical Capabilities

- Wet Analysis: Precise titrations for alkalinity, acidity, zinc content, and contaminants in Pretreatment and E-Coat baths.

- Performance Testing: Simulating harsh environments via Salt Spray Tests, Impact tests, and Cross-cut adhesion tests.

- Reporting: Detailed technical reports with data-driven recommendations.

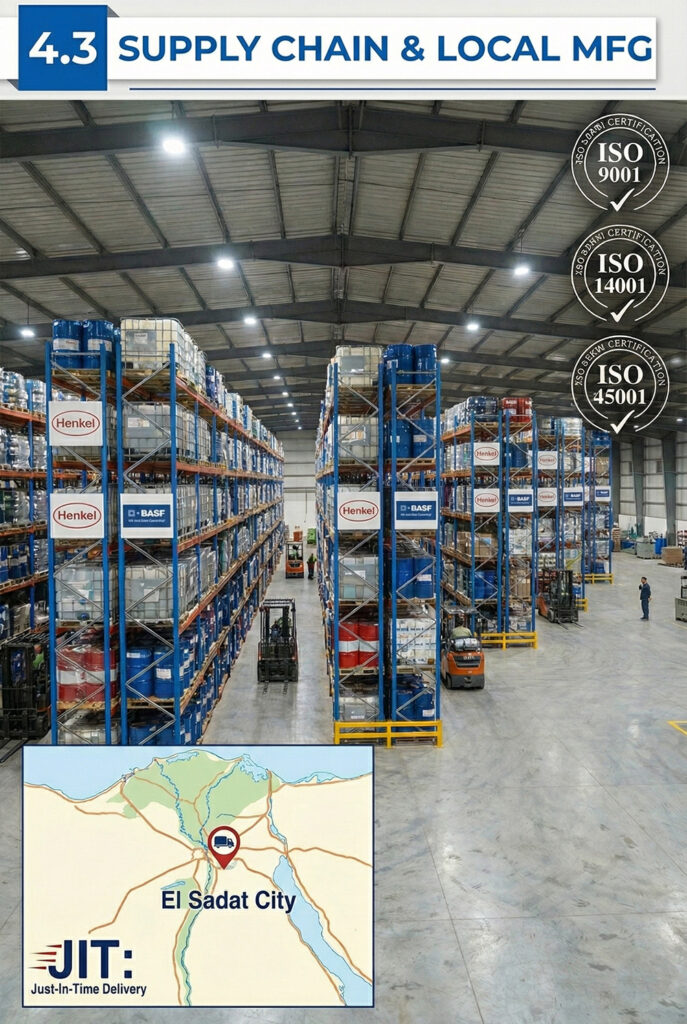

Supply Chain & Local Manufacturing

Availability is key. With our strategic location in Sadat City, we offer a massive competitive advantage in lead times and logistics. We apply Just-In-Time (JIT) delivery to reduce client inventory costs. Furthermore, we possess local manufacturing capabilities for high-quality solvents and auxiliary chemicals.

Key Pillars

- Local Content: Flexible local production to overcome import challenges and save foreign currency.

- Certified Quality: Operations managed under ISO 9001, ISO 14001, and ISO 45001

- Strategic Inventory: Maintaining safety stock of critical imported raw materials (from Henkel & BASF) to ensure uninterrupted production for our clients.